To read the original full thread and post questions/comments on this topic, please go to http://www.fjcruiserforums.com/foru...-roof-rack-lights-wiring-gauge-installation-w-pics-part-1-2-3-a.html#post961610

I decided to make up a “How-To” install roof rack lights wiring and switch and gauge installation. I have noticed that there are many threads with a little bit of everything, I wanted to have one place for everything.

![Image]()

This will be done in many parts as the work is completed. I will add pictures with a list of required tools and supplies that will also be needed to accomplish the work in a very professional type of wiring installation. I will also go into some detail of the reasons of why I picked certain items than others. This may help you decided on what you want to accomplish.

The first thing you need to do is establish where everything is going to go. Another words, you need to layout in your mind where your switches and the types that you want to use will be in the interior of the vehicle. It is also very important to layout any future items that you may want to add also.

I decided to use the small panel located along the driver’s side under the vent. I have seen other post that there isn’t enough room there. I have found after removing the panel, there is plenty of room for what I want to do.

I have the following lights on the vehicle that will need switches.

I first laid them out like I stated above where I wanted to have the switches located. I bought a couple of the OME switches for the vehicle with harnesses from one of the forum venders about a year ago. I noticed I do have room in the center console to add my switches in there, but decided against it for a couple of reasons. One is, it’s very easy to “bump” and turn on one of the switches in that location. I would not want to be running around in the daytime with my roof lights all on. I wanted something of a safety feature incorporated in the layout and design.

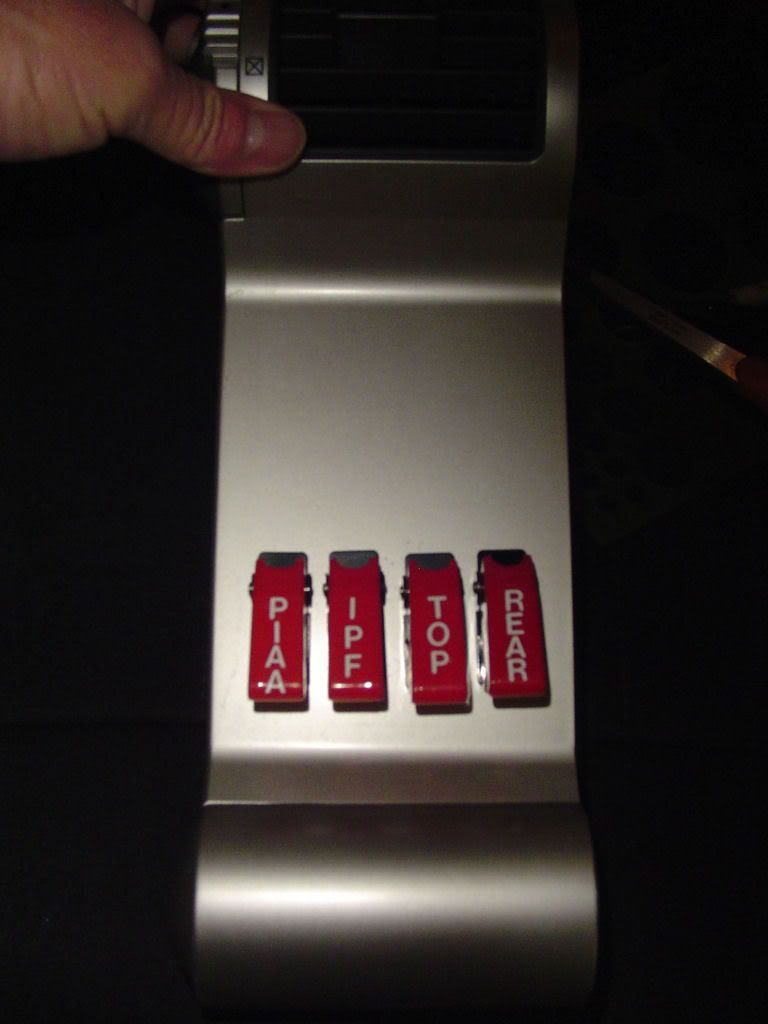

I decided to go with the racing type toggle switches that incorporate a safety cover over the top of the switches. Most of you have seen the type of switch I’m talking about, it has a flip up cover on them. When you turn them on, the cover has to be lifted and when turning them off, just push the cover down which shuts off the lights. These types of switches are also used in the aircraft industry.

I decided to mount four of them along the bottom portion of the panel and then add an Air gauge with switch above them.

Before writing this up I had already mounted the four switches as you can see in the picture.

![Image]()

To remove the panel, just grasp from the bottom portion of it, and pull outwards. This will unseat the tabs that hold the bottom portion of it. DO not pull any harder than is necessary, it will only pull out about an inch then grasp the top portion around the vent. Pull outwards straight out. The whole panel will pop right out.

![Image]()

As you can see, there is plenty of room to mount switches behind this panel.

![Image]()

Next after removing the panel, I took it back to my work shop. I first placed masking tape over the area I will be working on so as not to damage any part of the front panel. This also gives me a place to mark my locations for drilling.

![Image]()

I noticed that where I want to mount my switch for my Air Compressor there is a tab located in the way. After examining the rear of the panel carefully, I decided I can get by without this one tab that holds the panel on to the dash. I first drilled a hole of where the switch will go.

![Image]()

Then turning the panel over I used a Dremel tool to remove the rest of the tab on back, this allowed for a flat surface to mount my switch.

![Image]()

I next drilled out the gauge hole and used a Dremel tool to sand away a little more material away so the gauge would fit perfectly.

![Image]()

I than test fitted the gauge and mounted the Air Gauge switch on to the panel.

![Image]()

Sorry for the blurry pics in some of these, I didn’t realize they were this bad when I took them. But I think you can get the idea.

I next had to shorten the gauge holding bracket on the rear of the gauge. It is way to long for this application. I’m already a little tight on space back there. I used a marker to mark the location where I wanted to remove excess material from the bracket, I then cut it off with the Dremel tool again at an angle since I’m using an angle gauge mount on the front.

![Image]()

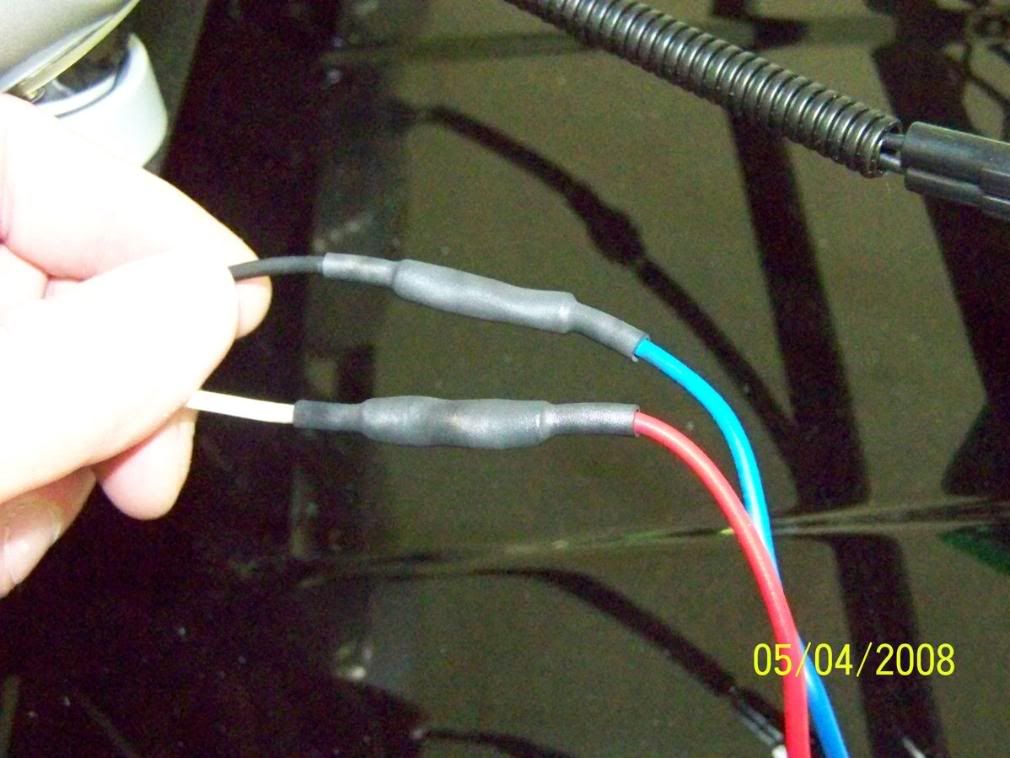

Now it’s time to test fit in the dash to make sure anymore of the inside plastic needs to be removed. I also went ahead and wired back up two of the lights I had already had hooked up to the switches. These were my PIAA’s and the two IPF’s on the front bumper.

![Image]()

I installed the panel back in the dash and everything fit perfect, here is a couple of pics of the finished product.

![Image]()

![Image]()

Part two of this install will be installing all the roof lights and wiring along with my Lowrance BAJA 540C GPS antenna which by the way I have to make a mount for on the rack. I will also go into detail listing all the tools and electrical connections that you will need for the install.

I decided to make up a “How-To” install roof rack lights wiring and switch and gauge installation. I have noticed that there are many threads with a little bit of everything, I wanted to have one place for everything.

This will be done in many parts as the work is completed. I will add pictures with a list of required tools and supplies that will also be needed to accomplish the work in a very professional type of wiring installation. I will also go into some detail of the reasons of why I picked certain items than others. This may help you decided on what you want to accomplish.

The first thing you need to do is establish where everything is going to go. Another words, you need to layout in your mind where your switches and the types that you want to use will be in the interior of the vehicle. It is also very important to layout any future items that you may want to add also.

I decided to use the small panel located along the driver’s side under the vent. I have seen other post that there isn’t enough room there. I have found after removing the panel, there is plenty of room for what I want to do.

I have the following lights on the vehicle that will need switches.

- PIAA Driving Lights (Bumper) – 1 Set

- IPF Driving Lights (Front Grill) – 1 Set

- IPF Spot Lights (Front Roof Rack) – 2 Sets

- Flood Lights (Rear Roof Rack) – 1 Set

- Future VIAIR Air Compressor w/ Storage Tanks (Sleep/Storage Box) – Switch & Gauge

I first laid them out like I stated above where I wanted to have the switches located. I bought a couple of the OME switches for the vehicle with harnesses from one of the forum venders about a year ago. I noticed I do have room in the center console to add my switches in there, but decided against it for a couple of reasons. One is, it’s very easy to “bump” and turn on one of the switches in that location. I would not want to be running around in the daytime with my roof lights all on. I wanted something of a safety feature incorporated in the layout and design.

I decided to go with the racing type toggle switches that incorporate a safety cover over the top of the switches. Most of you have seen the type of switch I’m talking about, it has a flip up cover on them. When you turn them on, the cover has to be lifted and when turning them off, just push the cover down which shuts off the lights. These types of switches are also used in the aircraft industry.

I decided to mount four of them along the bottom portion of the panel and then add an Air gauge with switch above them.

Before writing this up I had already mounted the four switches as you can see in the picture.

To remove the panel, just grasp from the bottom portion of it, and pull outwards. This will unseat the tabs that hold the bottom portion of it. DO not pull any harder than is necessary, it will only pull out about an inch then grasp the top portion around the vent. Pull outwards straight out. The whole panel will pop right out.

As you can see, there is plenty of room to mount switches behind this panel.

Next after removing the panel, I took it back to my work shop. I first placed masking tape over the area I will be working on so as not to damage any part of the front panel. This also gives me a place to mark my locations for drilling.

I noticed that where I want to mount my switch for my Air Compressor there is a tab located in the way. After examining the rear of the panel carefully, I decided I can get by without this one tab that holds the panel on to the dash. I first drilled a hole of where the switch will go.

Then turning the panel over I used a Dremel tool to remove the rest of the tab on back, this allowed for a flat surface to mount my switch.

I next drilled out the gauge hole and used a Dremel tool to sand away a little more material away so the gauge would fit perfectly.

I than test fitted the gauge and mounted the Air Gauge switch on to the panel.

Sorry for the blurry pics in some of these, I didn’t realize they were this bad when I took them. But I think you can get the idea.

I next had to shorten the gauge holding bracket on the rear of the gauge. It is way to long for this application. I’m already a little tight on space back there. I used a marker to mark the location where I wanted to remove excess material from the bracket, I then cut it off with the Dremel tool again at an angle since I’m using an angle gauge mount on the front.

Now it’s time to test fit in the dash to make sure anymore of the inside plastic needs to be removed. I also went ahead and wired back up two of the lights I had already had hooked up to the switches. These were my PIAA’s and the two IPF’s on the front bumper.

I installed the panel back in the dash and everything fit perfect, here is a couple of pics of the finished product.

Part two of this install will be installing all the roof lights and wiring along with my Lowrance BAJA 540C GPS antenna which by the way I have to make a mount for on the rack. I will also go into detail listing all the tools and electrical connections that you will need for the install.