While at the RMTP Lobster Run in Maine, I did this...

When I came home my Idler Pulley's were screaming. I read the thread about cleaning the pulleys and followed it...

Then I found these sealed bearings from NAPA

Two upper and one tensioner pulleys

One lower pulley

Sealed front and rear, problem solved. Cleaned and repacked my originals for spares on the road.

OEM Pulley Top Side: (sealed)

![Image]()

OEM Pulley Under Side: (this is where the mud gets in)

![Image]()

NAPA Replacement Top Side:

![Image]()

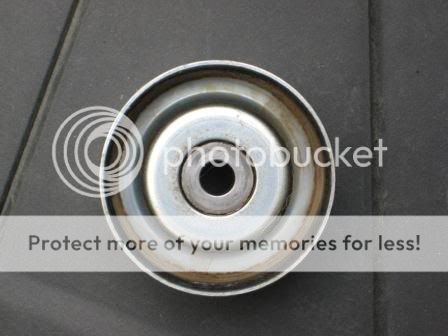

NAPA Replacement Under Side:

![Image]()

Hope this helps.

When I came home my Idler Pulley's were screaming. I read the thread about cleaning the pulleys and followed it...

Then I found these sealed bearings from NAPA

Two upper and one tensioner pulleys

One lower pulley

Sealed front and rear, problem solved. Cleaned and repacked my originals for spares on the road.

OEM Pulley Top Side: (sealed)

OEM Pulley Under Side: (this is where the mud gets in)

NAPA Replacement Top Side:

NAPA Replacement Under Side:

Hope this helps.